⦿ LOW STOCK

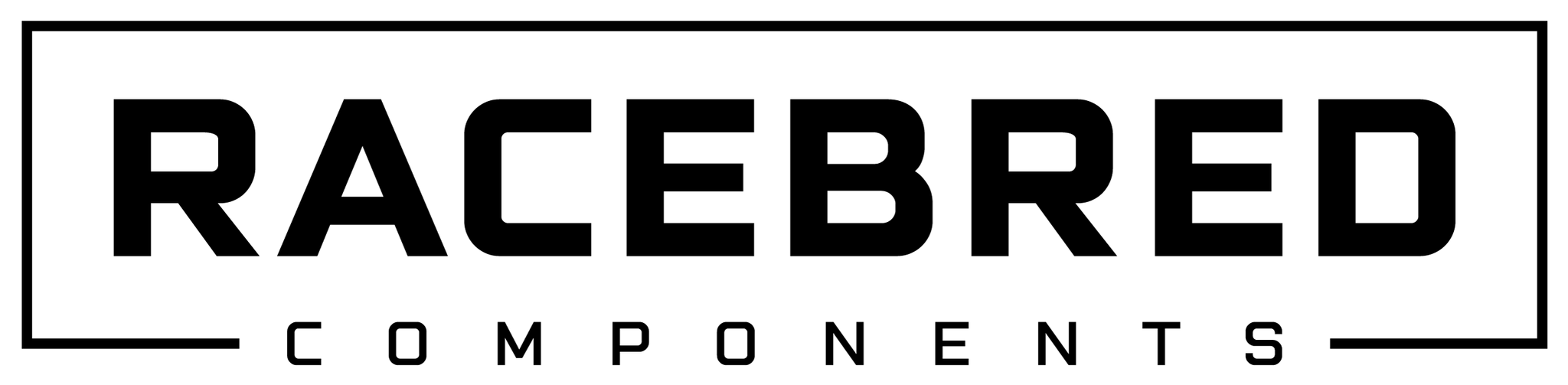

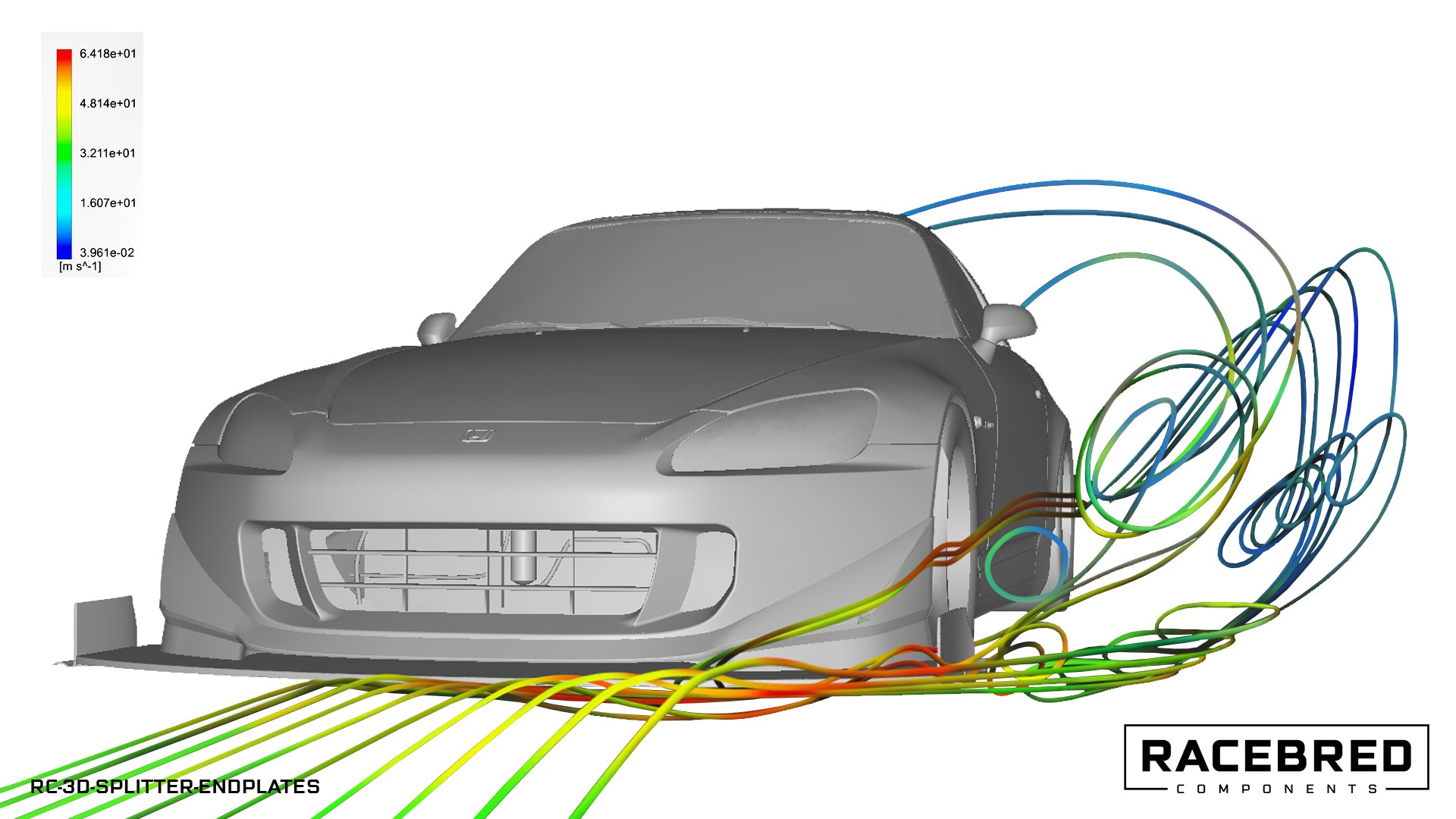

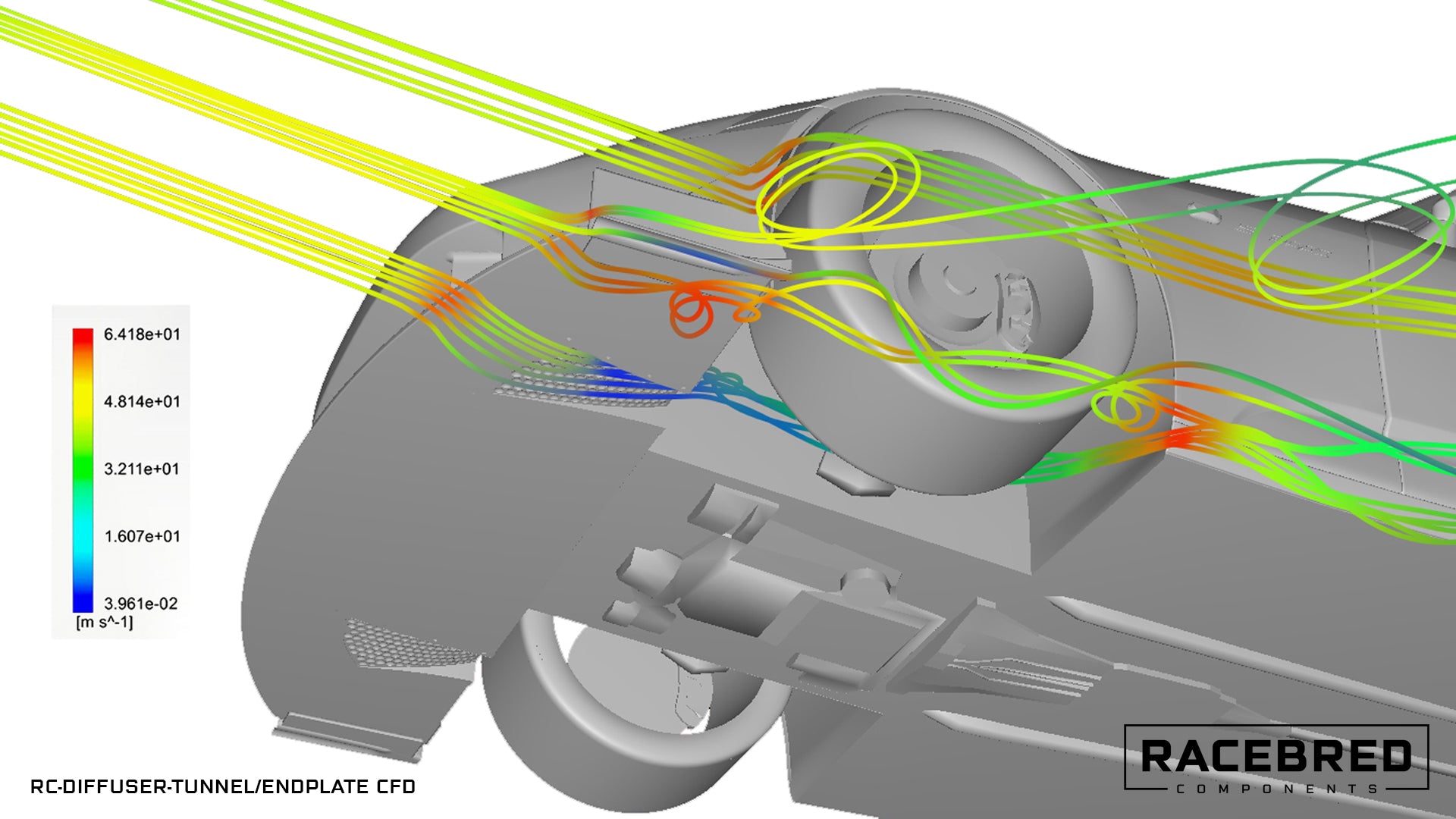

Racebred Components 3D Splitter Endplates were designed to help increase downforce by controlling the airflow on the outward ends and underside of the front splitter. Utilizing CFD analysis we were able to improve front-end downforce by creating a flow structure and outwash, leading to an increase in front grip.

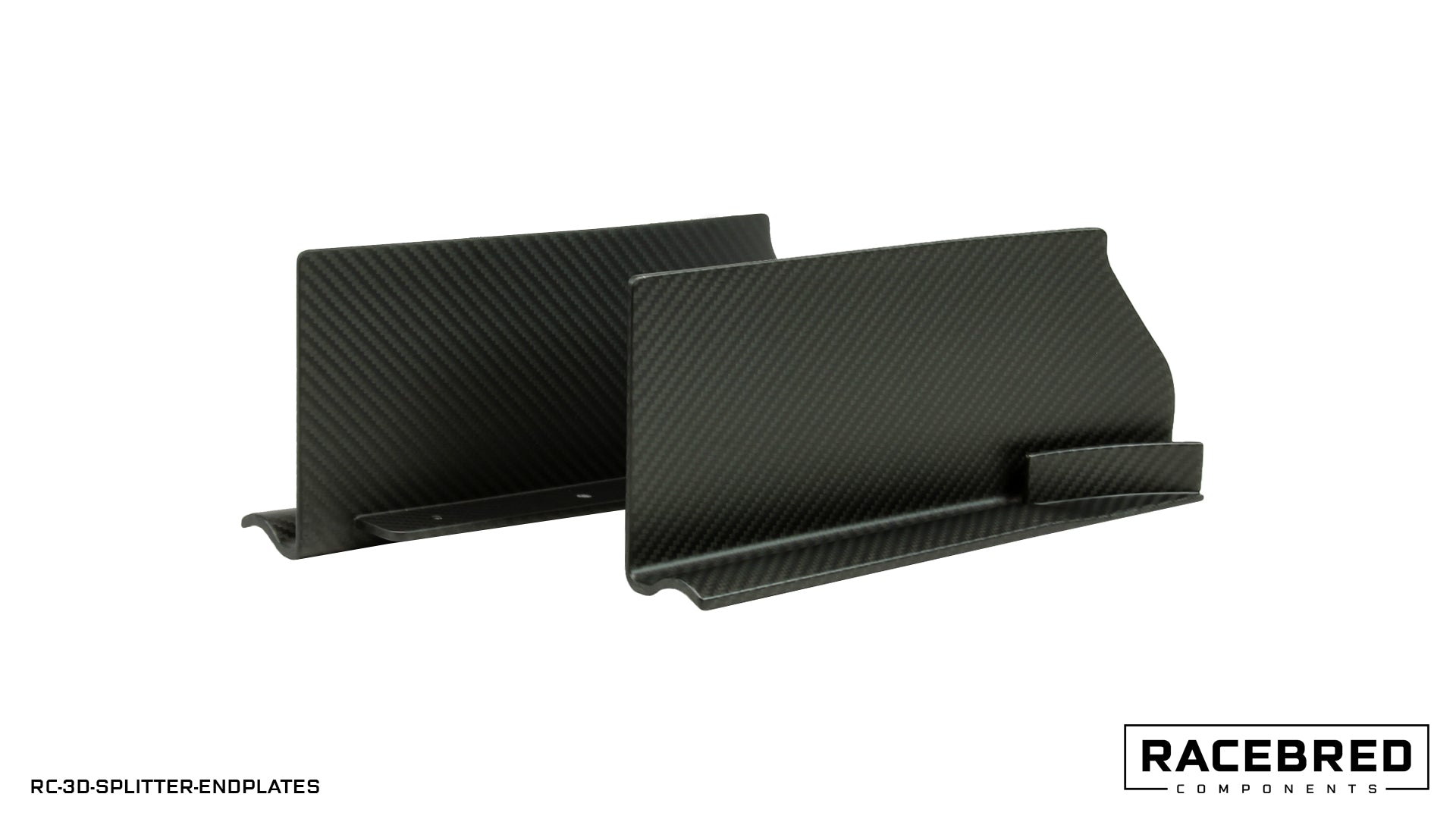

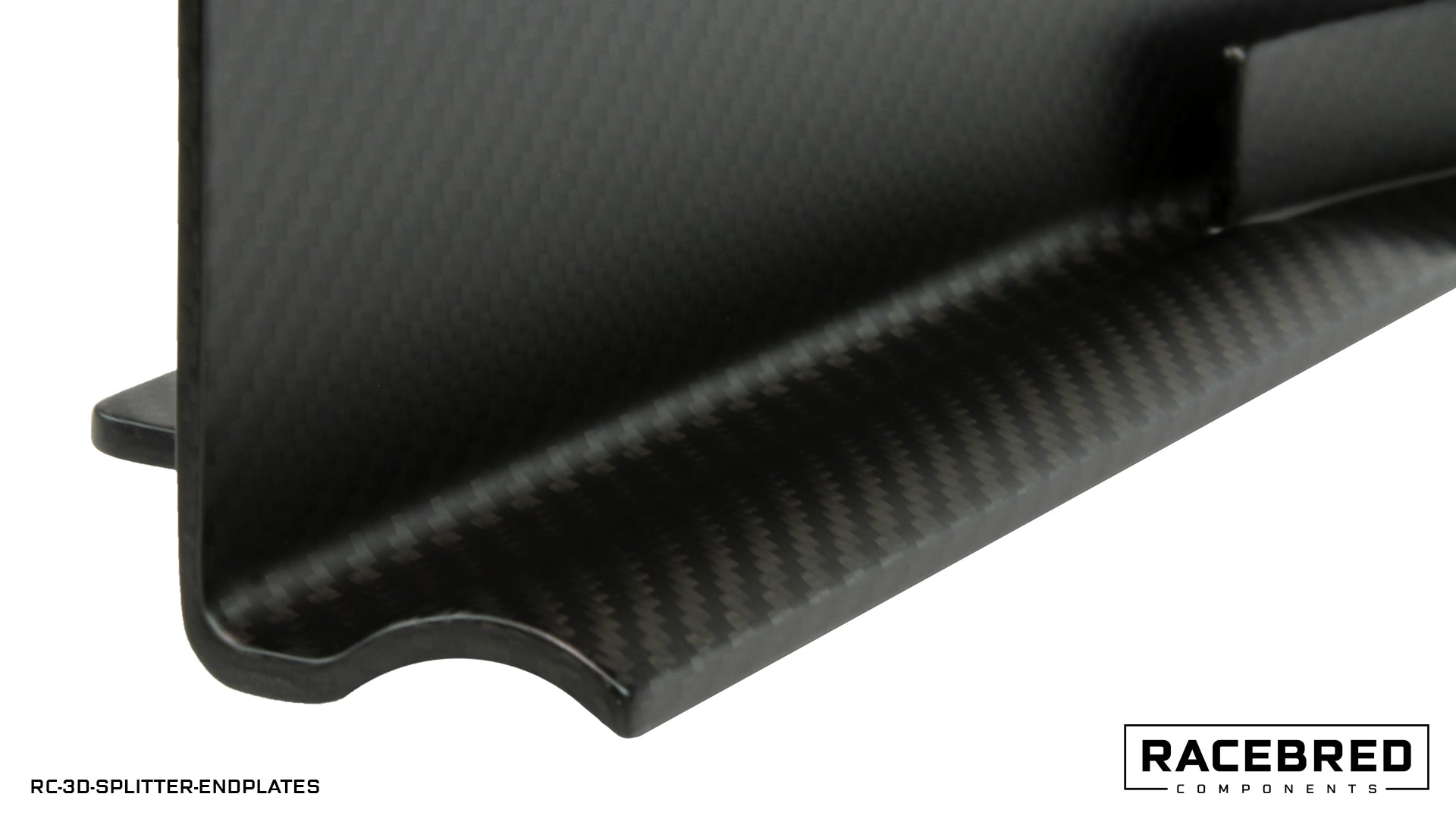

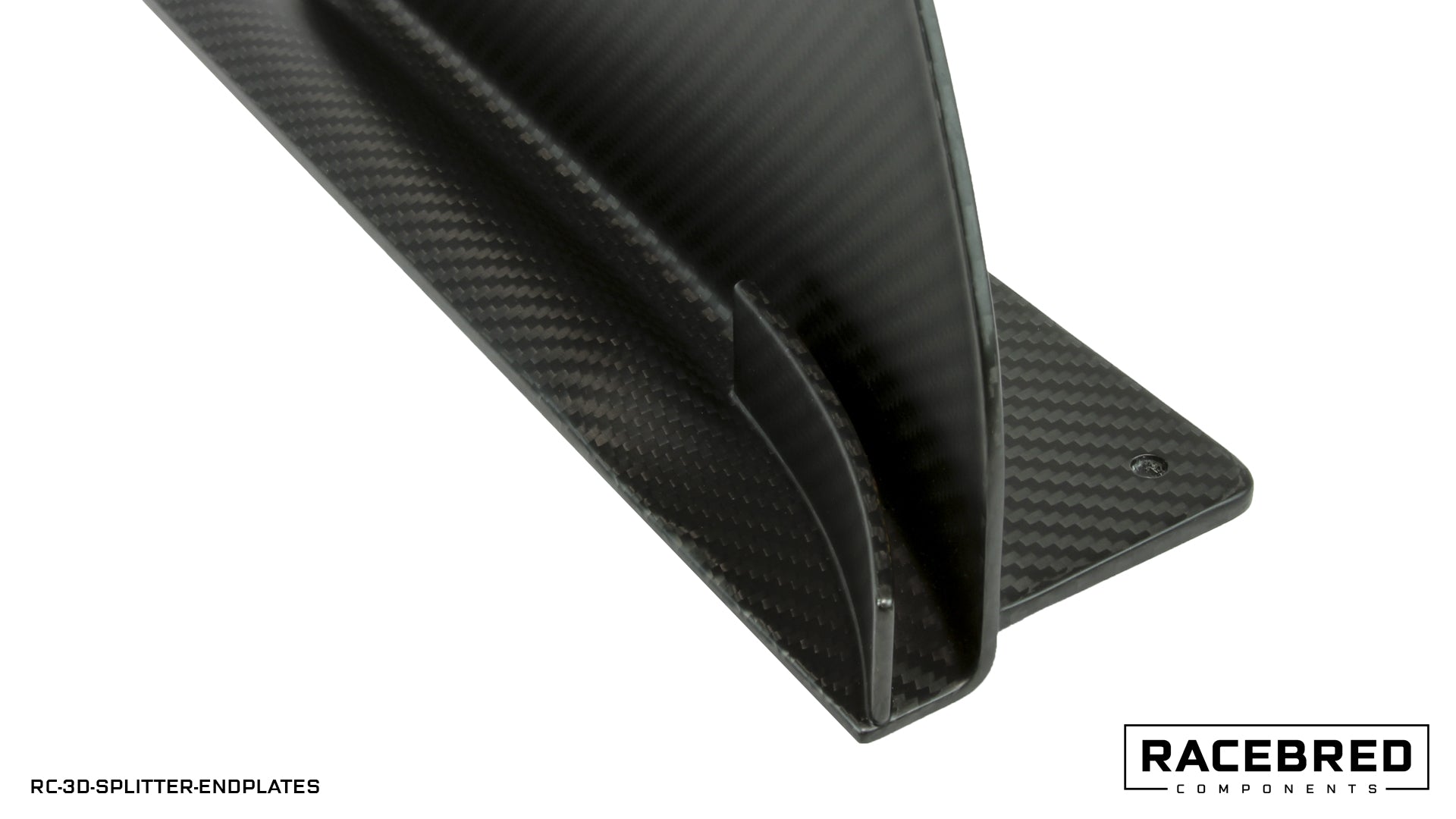

The 3D tunneled design helps create a seal at the edges of the splitter and joins the existing vortex created in the same rotation, while the flow conditioner at the rear functions to further redirect air outward past the front wheels.

ADVANTAGES OF PREPREG (DRY) VS. RESIN INFUSION (WET):

Our Racebred Components 3D Splitter Endplates utilize Prepreg Carbon Fiber and an autoclave curing process to produce the highest quality, lightweight and maximum strength motorsport grade product.

Prepreg carbon fiber provides concise resin ratio properties and eliminates variables usually seen in traditional wet resin layups, which can alter final tensile, modulus strength properties, and overall weight. Prepreg carbon fiber also offers superior weave uniformity and continuous repeatability compared to a resin infusion process mostly seen on other carbon fiber products on the market.

FEATURES:

- CFD Designed / Optimized

- Approximate 18% Downforce Increase @ 100mph*

- Prepreg Carbon Fiber - 2x2 Twill

- Autoclave Cured

- UV Matte Finish

- Universal Fitment

- 12" L x 5" H x 2” W

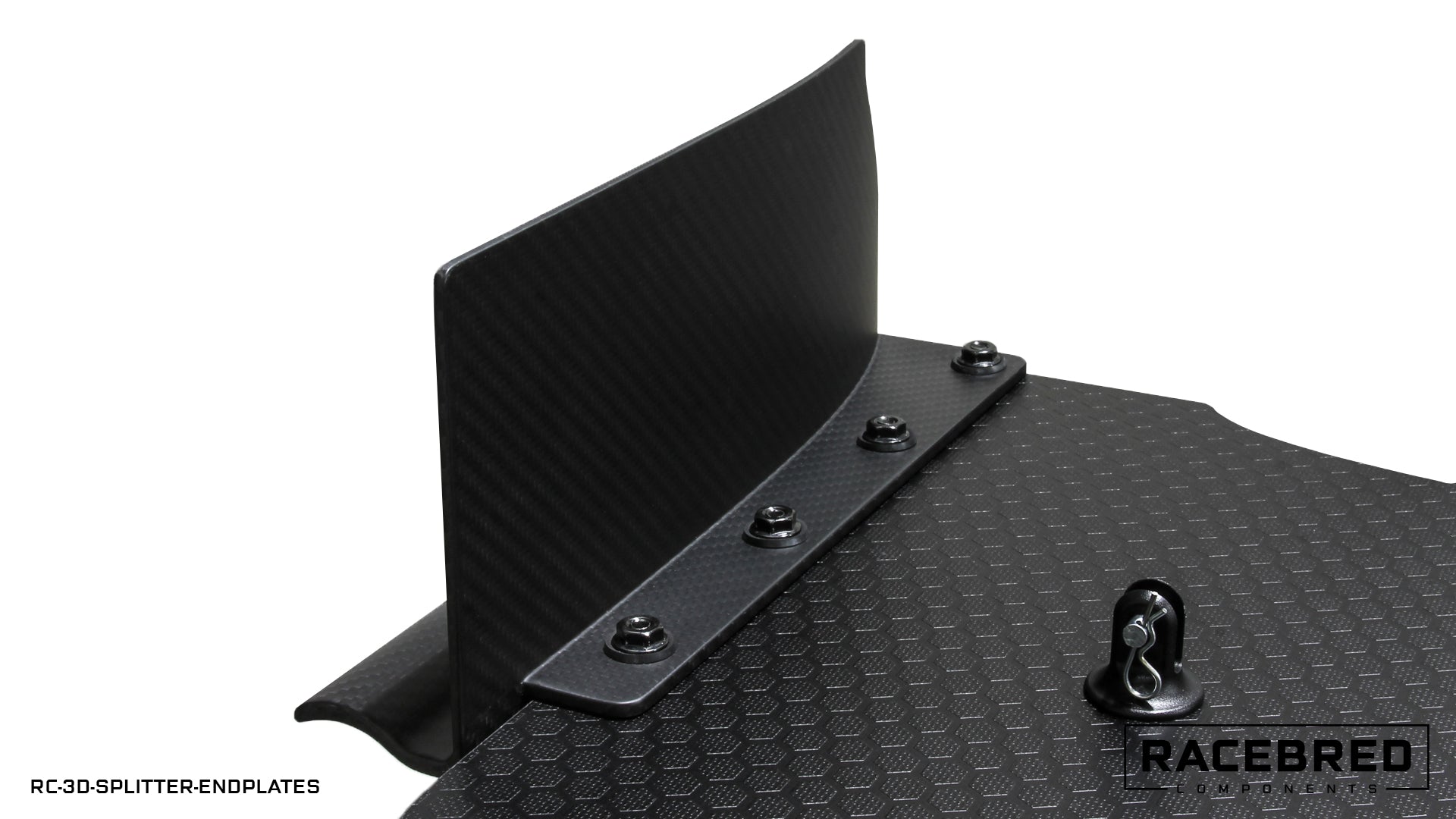

- Integrated Mounting Flange (11" L x 1.2” W)

- Pre-Drilled / Reinforced Mounting Holes

- 0.4lbs (Per Endplate)

WHAT’S INCLUDED:

- Dry Carbon 3D Splitter Endplates (Left & Right)

- Black Zinc Mounting Hardware

- Drilling Templates

PRODUCTION TIMELINE:

- IN STOCK